These solutions support reliable, scalable power delivery and help engineers reduce heat and weight in demanding applications.

Key Takeaways

-

Vicor’s modular DC-DC converters let engineers build flexible and easy-to-upgrade power systems, saving time and reducing costs.

-

These converters deliver high efficiency and power density, helping reduce heat and improve reliability in tough environments.

-

Vicor offers a wide range of products that cover many power needs, from power modules to circuit protection and accessories.

-

Engineers use Vicor converters in many industries like aerospace, automotive, and data centers to solve complex power challenges.

-

Vicor supports engineers with design help, strong supply chains, and technical resources to ensure project success.

Key Differentiators

Image Source: pexels

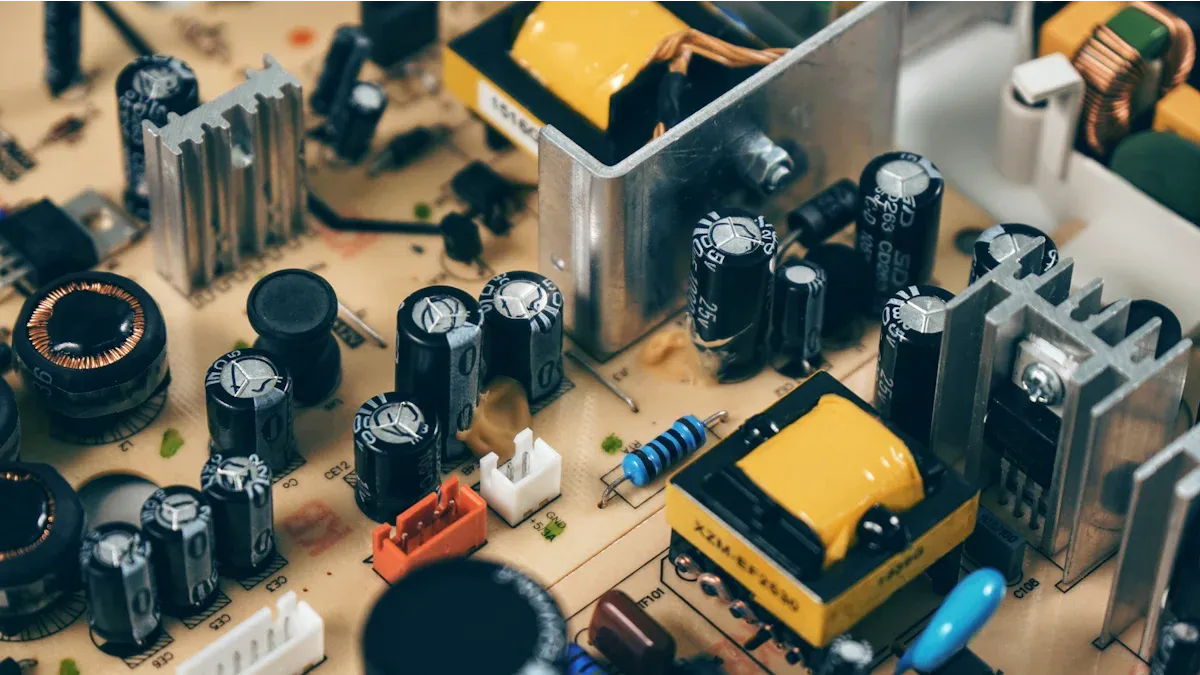

Modularity

Vicor’s modular, plug-and-play architecture stands out in modern power management. Design engineers can easily replace or combine subsystems, which allows for flexible system designs. This modular approach reduces risks and saves costs. It also makes technology upgrades and maintenance much easier. Program managers and engineers use modularity to guide system realization and apply standards and engineering tools.

Modular design supports streamlined engineering processes by enabling automation and efficient data handling. Engineers can map workflows into reusable components, which improves project team efficiency and design automation.

The following table highlights how modularity benefits engineering projects:

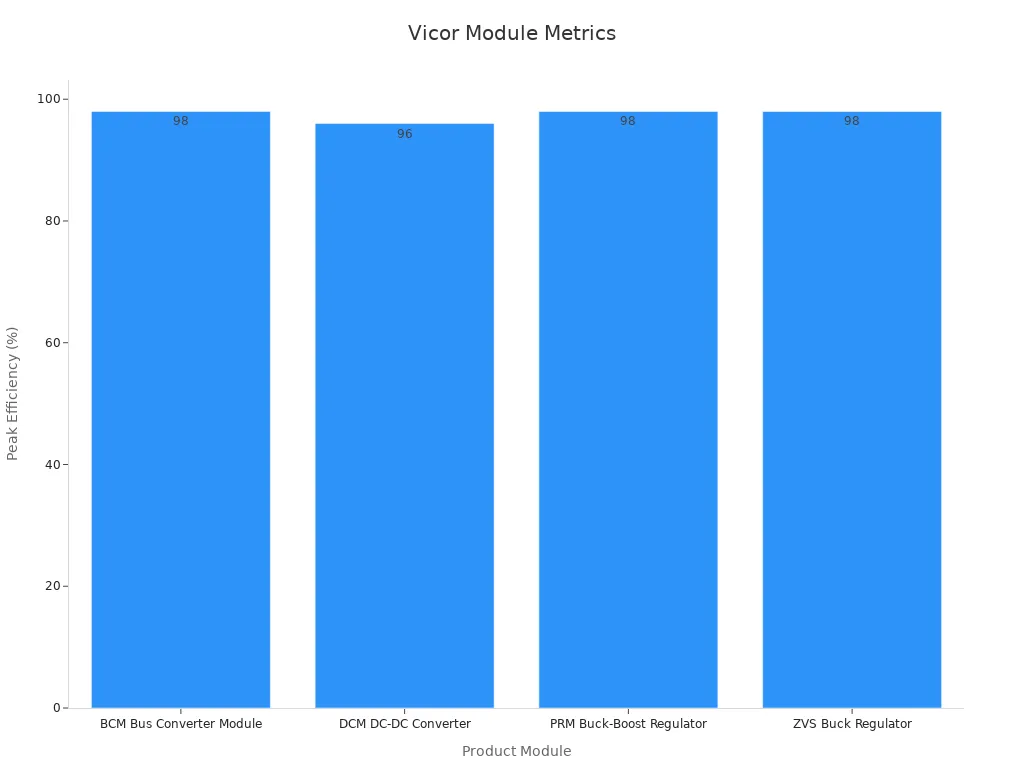

Efficiency

Efficiency remains a core strength of vicorcorporation DC DC Converters. These converters deliver high power density and maintain low ripple and noise. The compact form factor helps with thermal performance and system integration.

-

Power output ranges from 750W to 2kW.

-

Input voltage ranges from 40V to 60V.

-

Adjustable regulated output voltage between 10V and 12.5V.

The table below shows key efficiency measurements:

These features help engineers reduce heat and improve reliability in demanding environments.

Product Range

Vicor offers a comprehensive portfolio that covers the entire power chain. The range includes power bricks, semiconductor-centric solutions, and integrated circuits. Engineers can find DC-DC switching regulators, power distribution switches, load drivers, OR controllers, ideal diodes, and hot swap controllers. Discrete semiconductors such as diodes, bridge rectifiers, and FET/MOSFET transistors ensure robust power conversion and protection.

-

The product catalog includes a wide variety of components and accessories.

-

Categories span from power management ICs to circuit protection, inductors, coils, digital isolators, optoisolators, and temperature sensors.

-

Vicor also provides both external and internal AC-DC and DC-DC converters, configurable power supply chassis, and factory-assembled power supplies.

-

Accessories like hardware kits, evaluation boards, filters, fans, heat sinks, and connectors support complete system integration.

Quality assurance remains a top priority. Vicor sources all components from original factories or authorized agents. This ensures reliability and peace of mind for engineers and decision-makers.

vicor corporation DC DC Converters in Action

Image Source: pexels

Industry Applications

Engineers use vicor corporation DC DC Converters in many industries that demand reliable and efficient power. These converters support critical systems in aerospace, defense, data centers, automotive, and industrial sectors. Each industry faces unique power challenges, such as space limitations, heat management, and the need for high efficiency.

-

In aerospace, power modules must handle extreme temperatures and vibrations. Vicor’s converters deliver stable power for avionics and satellite systems.

-

Defense systems require rugged, reliable power for communication and surveillance equipment. Vicor’s solutions help maintain mission-critical operations.

-

Data centers need high-density power supplies to support servers and storage. Vicor’s converters reduce heat and save space, making them ideal for these environments.

-

Automotive engineers use these converters in electric vehicles and advanced driver-assistance systems. The converters help manage power between batteries, motors, and sensors.

-

Industrial automation relies on precise power delivery for robotics and control systems. Vicor’s products ensure smooth operation and protect sensitive electronics.

Application notes and user guides from Vicor show how engineers design high-power arrays and create custom voltage outputs. Articles highlight the use of these converters in network switches and edge computing, where efficiency and reliability are essential.

Real-World Use Cases

The following table shows how vicorcorporation DC DC Converters solve real-world power challenges across different sectors:

These examples show how engineers use Vicor’s converters to solve complex power problems. The converters support innovation and reliability in demanding environments.

Technical Innovations

Image Source: pexels

Advanced Features

Modern power management systems rely on advanced features to improve efficiency and reliability. Vicor corporation DC DC Converters use modular design and digital control to help engineers build flexible power systems. These converters support automation and data integration, which makes them suitable for complex projects.

-

Data preparation gathers and validates information from many sources. Software automation ensures data stays accurate.

-

Engineers use advanced algorithms and machine learning to analyze large sets of power data. This helps solve real-world problems quickly.

-

Results appear in clear reports or dashboards. Automated systems can even take action based on the analysis.

The power industry now uses big data to solve problems and create new ways to operate. Automated analysis of electronic devices and custom algorithms for fault detection improve system performance.

Circuit Protection

Circuit protection keeps sensitive electronics safe from damage. Vicorcorporation DC DC Converters include many protection components. These include transient voltage suppressors, varistors, fuses, and gas discharge tube arresters. Each part helps prevent power surges and electrical faults.

-

Digital isolators and optoisolators provide safe separation between circuits.

-

Inductors and coils store energy and filter out unwanted signals.

-

Power management ICs, such as hot swap controllers and ideal diodes, add extra layers of safety.

These features help engineers design systems that stay reliable, even in harsh environments.

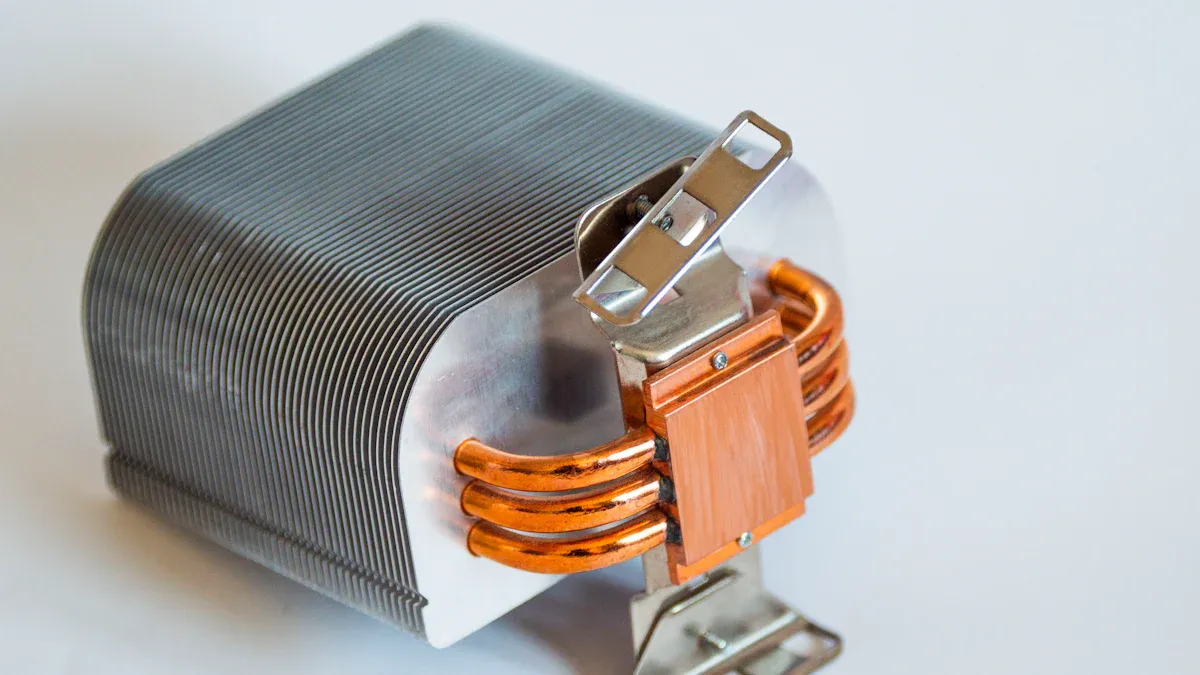

Thermal Management

Thermal management ensures that power systems run cool and last longer. Engineers use materials like copper and aluminum to move heat away from sensitive parts. Simulation tools, such as Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA), predict where heat will build up.

-

Simulations show temperature patterns and help find hot spots.

-

Engineers use thermal cameras and sensors to check real-world performance.

-

Design changes, like adding heat sinks or changing material thickness, improve cooling.

AI and machine learning now help optimize thermal designs. These tools analyze large data sets and suggest new ways to manage heat. Applications for these strategies include electronics, cars, planes, and power plants.

Support and Services

Image Source: pexels

Design Assistance

Vicor supports engineers at every stage of the design process. Their team offers guidance on selecting the right DC-DC converters, optimizing layouts, and solving technical challenges. Many engineers report faster project completion and improved collaboration when using design assistance. For example, a mechanical team lead in robotics noted that a centralized design review dashboard improved task management and review efficiency. An engineering manager in manufacturing saw better communication and reduced design stress.

Vicor’s design assistance helps teams reduce errors, improve quality, and speed up product development. Their experts also support rapid prototyping and customization, making it easier to meet unique project needs.

Supply Chain Solutions

A strong supply chain ensures that engineers receive components on time, even during disruptions. Vicor’s global network sources products directly from original factories or authorized agents. This approach protects quality and reliability. Leading companies in power management, such as Schneider Electric, have shown that robust supply chains can deliver sustainable operations and adapt to challenges. Strategies like flexible supply bases, recovery planning, and integrated planning tools help maintain supply and demand balance.

-

Vicor’s supply chain adapts quickly to changes in demand.

-

Strategic stock and flexible sourcing reduce the risk of shortages.

-

Integrated planning tools support fast recovery from disruptions.

These practices give engineers confidence that their projects will stay on track.

Technical Resources

Vicor provides a wide range of technical resources to support engineers. Their website features datasheets, application notes, and user guides. Engineers can access evaluation boards, design tools, and simulation software. Technical support teams answer questions and help solve problems quickly.

Vicor’s resources help engineers make informed decisions, improve designs, and achieve better results. Their support extends from initial concept to final production, ensuring success at every step.

Engineers choose vicorcorporation DC DC Converters for their modular design, high efficiency, and wide product range. These converters help solve complex power challenges in many industries. Vicor offers strong technical support and reliable supply chain solutions. Their products improve system performance and reliability. Readers can explore Vicor’s solutions to meet the needs of their next power management project.

FAQ

What makes Vicor DC-DC converters different from others?

Vicor DC-DC converters use modular designs and high-density technology. These features help engineers build flexible and efficient power systems. The converters also offer strong protection and easy integration.

Can engineers use Vicor converters in harsh environments?

Yes. Vicor designs its converters to work in tough conditions. They handle high temperatures, vibrations, and electrical noise. Many industries trust Vicor for reliable performance.

How does Vicor support engineers during design?

Vicor provides design tools, technical guides, and expert advice. Their team helps engineers choose the right products and solve problems quickly.

What types of products does Vicor offer?

Vicor’s wide range covers many power needs.

To learn more about VICOR's product needs, please contact us